Profinet

Posted on 21 August, 2022

What is PROFINET?

PROFINET is a mechanism to exchange data between controllers and devices. It is a full duplex system that ultilises integrated switches to connect its network components.

Using an integrated switch, the field device can make two (or more) ports available externally. These switches must support negotiation of transmission parameters and autonomous crossing of send and recieve lines. The switches must also be able to support VLAN tagging with prioritisation for reliable RT communication in PROFINET networks.

PROFINET Device Classification

PROFINET IO classifies devices into three types; IO-Controllers, IO-Devices and IO-Supervisors. IO-Controllers are devices that execute an automation program. Controllers, functionally similar to a PROFIBUS Class 1 Master, exchange data with IO-Devices. IO-Devices are distributed sensor/actuator devices connected to the IO-Controller over Ethernet. In Profibus terms, IO-Devices are similar to PROFIBUS slaves. IO-Supervisors are HMIs, PCs or other commissioning, monitoring or diagnostic analysis devices. These devices are similar to Class 2 PROFIBUS Masters.

IO-Controllers map IO data from PROFINET IO devices into the process image of the controller. In Siemens S7 programmable controllers, I/O data, alarms and status data is mapped into the process image in much the same way it is done for PROFIBUS devices. These data values are then available for use by the control program. IO-Controllers must support the following kinds of services:

- Cyclic Data Exchange – The exchange of data between IO-Controllers and IO-Devices

- Acyclic Data Exchange – The exchange of Configuration and Diagnostic data

- Alarms – Alarm data exchange from an IO-Device to an IO-Controller

- Context Management – Connection processing

IO-Supervisors are used for commissioning and diagnostic data collection. IO-Supervisors can read and write internal diagnostic data associated with the PROFINET IO stack or diagnostic data provided by the application program of a device. IO-Supervisors can also read and write configuration data using special, non-cyclic record data object services. These types of devices may only be used during the commissioning process or they may be used as an HMI to display diagnostic data to the end user.

PROFINET field device is always modular in design. A PROFINET IO system requires at least one IO-Controller and one IO-Device. Systems can be assembled in various configurations: multiple IO-Controllers for a single IO-Device; single IO-Controllers for multiple IO-Devices and multiple IO-Controllers with multiple IO-Devices.

Networks

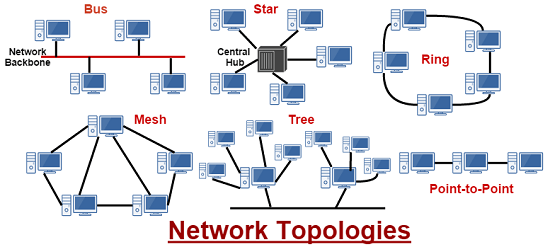

PROFINET networks are primarily deployed using line topology, which reduces the number of cables needed. Here are some of the topologies supported:

image source: https://refugeictsolution.com.ng/2021/02/21/understanding-computer-network-topology/

• Line topology, which primarily connects

terminals with integrated switches in the field

• Star topology, which requires a central switch

located preferably in the control cabinet.

• Ring topology, in which a line is closed to form

a ring in order to achieve media redundancy.

• Tree topology, in which the topologies

mentioned above are combined.

PROFINET follows the provider/consumer model for data exchange over Ethernet. This means IO controller and devices can spontaneously send cyclic data independently. Ethernet also gives PROFINET the ability to provide faster updates, more bandwidth, larger messages, an unlimited address space, and even more diagnostic capabilities.

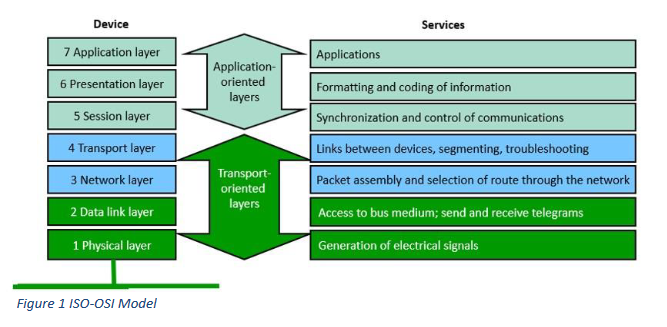

7-lsyer ISO-OSI model

source: https://us.profinet.com

Not all layers are used at al times, it really depends on the application. But to summarise, we can collaspe the 7 layers down to 4-

Layer 1 & 2: Ethernet, Layer 3: IP Layer, Layer 4: TCP/UDP (Transmission control protocol, User Datagram protocol) layer, Layer 7: Application Layer.

One random information: All thanks to the LLDP (Link Layer Discovery) protocol, PROFINET field devices know their neighbors! The LLDP protocol is used to exchange the available addressing information over each port, allowing the respective port neighbor to be uniquely indentified and therefore, determinating the physical structure of the network.

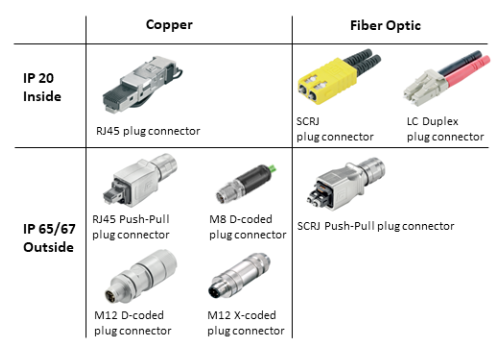

Cables and connectors for PROFINET

Detailed information on PROFINET plugs can be found in the "PROFINET Cabling and Inter-connection Technology" guideline available for download: www.profibus.com/pncit

But here is a quick guide on PROFINET industrial plug connectors:

source: https://us.profinet.com

PROFINET also supports function for process automation- CiR, redundancy, time synchtronization, and time stamping. (This is another whole big topic that we can explore on another day)

All these do come with a cost; PROFINET infrastructure is on average more costly than others. However, given how technologies are evolving, it may pay to invest in the future!